9 Questions to Ask Before Starting A Container Project

1. Why are container buildings so popular?

Shipping container buildings are popular due to their cost effectiveness, speed of construction and sustainability.

Turning a steel shipping container, also known as a conex box, sea can or ISO container, into a building can save you money for several reasons.

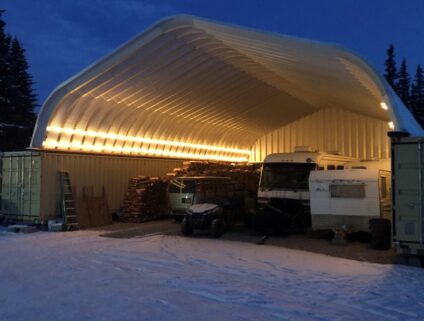

Once you have your shipping containers purchased, Conex box buildings can be assembled quickly—all you have to do is add a roof!

A container cover roofing system can be quickly constructed with a small crew and minimal effort, saving you the cost of labor and allowing you to use your building as soon as possible.

Since shipping containers are used as the base of the storage building, you can save money on a concrete foundation.

Finally, many find container buildings appealing because they are eco-friendly. Sea can buildings are a great sustainable building option because they’re made from recycled containers.

By repurposing a shipping container into a building, you’re essentially recycling thousands of pounds of steel.

MORE INFORMATION ON CONTAINER COVERS

2. What are container buildings used for?

With ingenuity and imagination, the sky is the limit with container building uses.

These structures are already used for a variety of commercial and residential applications, including:

- Workshop

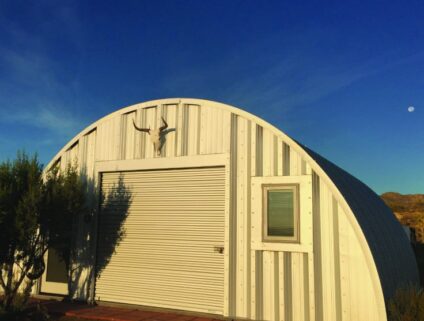

- Garages

- Job site storage/tool room

- Office buildings

- Vehicle and equipment storage

- Secure storage/Clean room

3. What dimension shipping container will I need?

When creating your container building plans, consider the use of your building to help determine your ideal building size.

Shipping containers are typically 20’ or 40’ in length. A 20’ container is about the size of a standard parking spot. A 20ft container holds about 1,150 cubic feet and could comfortably hold one to two room’s worth of items.

A 40ft container is about the size of a two car garage and can hold the equivalent to about two to three rooms. They’re better for projects that require a lot of storage space and have a lot of space for shelving.

If you plan to store taller items, you might want to opt for a high cube container. A high cube container is one foot taller (9’6”) than the standard height container (8’6”).

4. How will I group my containers?

After you determine the dimension of your shipping containers, you must decide how to group the containers.

The intended dimensions of your building will help you determine the way you group your containers. For example, you can figure out how close or far apart the containers will be based on the width of your building.

If you’re storing taller equipment, you also have the option to stack containers on top of each other for extra height.

5. What are some roofing options for container buildings?

One of the easiest options to convert ISO containers into buildings is to cover the space between shipping containers with a steel roofing system kit.

SteelMaster’s container roofing kits can be tailored to fit any job site. They are pre-engineered to meet the local wind, snow and seismic design requirements of any location.

The roofs can be mounted on the outer edge of the container or the inner edge of the container.

Your mounting location can depend on several factors, including:

- Water run-off placements

- The height/radius of the roof

- If storage under the roof is a priority

An outside mount helps with keeping water from getting inside because when the plate is over the edge of the container, the water runs off.

Outside mounts also allows for extra dry storage on top of boxes, with an additional useable 640 square feet under the roof.

An inside mount is narrower, therefore stronger (possibly in a lighter gauge) but either way, less material means less weight and less cost.

6. How do I get shipping containers?

There are two main ways to purchase a shipping container: buy from a third party seller or buy from a local supplier.

If you purchase online, you have a variety of options to choose from because the seller could be from anywhere in the world. Buying from sites like eBay or Craigslist usually mean the price is negotiable and you can find a great deal because the owner is eager to sell.

However, there are also many benefits to purchasing a shipping container from a local supplier. Local suppliers are usually knowledgeable about permitting requirements in your area.

Unlike online sellers, some local suppliers will offer special features like locking mechanisms, doors and shelving for an added cost. Plus, the deliver/shipping fee is usually cheaper because of shorter distance.

7. Is my site level?

Before you place your shipping containers at your build site, you must make sure the ground is level.

Leveling your building site provides uniform base for your structure. If the ground isn’t level, your building could end up leaning to one end or one side. Plus, if your building isn’t balanced, your roof panels, sides and ends may not line up properly.

To prepare your building site before leveling, remove items that could affect the base quality like debris, rocks and trees. Make a space wide enough to allow workers and equipment to move around the building site.

8. Do I need a permit?

Check with your local municipality, county and city to determine your local building code requirements. It is important to do this research before your container is even delivered onsite, because failure to do so could result in a fine.

Earlier in 2019, the International Code Council voted to incorporate shipping containers in the 2021 International Building Code. Once the amendment is incorporated, building code officials will be able to turn to the International Code Council’s guidelines for explanations on permitting shipping containers.

Typically, permits are easier to obtain for temporary storage solutions. In some of these cases, a permit is not required at all. Rural farmland or areas beyond local city limits are usually more forgiving with their permit requirements.

9. What are options for customization?

There are many ways to customize your container building, the most common being parts and accessories. Some examples include:

Container buildings can be open ended or enclosed with endwalls. SteelMaster’s endwalls are about the same cost of our prefabricated arches, as the height is usually 18 feet or more.

SteelMaster’s solid endwalls are pre-cut and pre-punched for ease of assembly. The panels bolt together using the same one-size nut and bolt system used for the arches.

If your building is enclosed on both ends, you’ll need to purchase a door. Garage doors can be added when a larger entrance is needed. Typically, garage door frames are mounted in the center of the endwall.

Service doors, also known as man doors, can also be added for ease of access. The appropriate location of a service door frame depends on the building’s configuration.

Download Our Container Cover Product Guide

Categories

Tags