Hawaii FBO Upgrades Maintenance Shelter with Container Cover Building

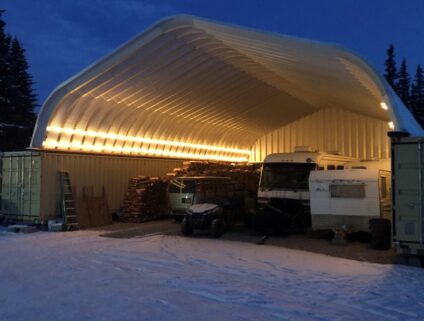

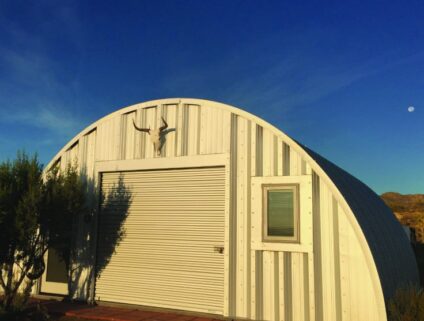

After using a maintenance shelter made of weak materials for years, the folks at Air Service Hawaii decided to upgrade to a more durable and functional solution by using two shipping containers and a SteelMaster container cover roof kit.

“The previous structure that was here was sort of an ad hoc, hodgepodge of the roof and flimsy supports and an old container van,” said Air Service Hawaii’s President, Shaen Tarter.

Air Service Hawaii is a Fixed-base Operator (FBO) that has been in business since 1948 and has six airports. The company’s main business is providing ground handling and fuel to business jets visiting Hawaii or just passing through the state.

They also provide refueling to some commercial airlines throughout the state, helicopters for touring companies, and flight schools around Hawaii.

Shaen saw photos of container cover structures online and discovered SteelMaster after a quick Google search. He says he chose SteelMaster’s shipping container roof kit for several reasons, the key factor being the amount of headroom due to the structure’s clear span design.

“The arch is necessary to create the strength, but also gives you the benefit of having a lot of headroom,” Shaen said. “In our case, the more headroom the better, the more breeze that gets in there for trucks and equipment that’s pretty tall off the ground.”

SteelMaster’s B2B Operations Manager, Jon Hunter, worked with Shaen’s engineer in Hawaii to help design a maintenance shelter that fits the company’s needs.

“We needed something that would comply with hurricane standards and be acceptable for the airport, to provide a nice airy secure space to do our work,” Shaen said. “Your solution was the best one for the space that we had without requiring us to relocate to another place.”

Shaen’s employees were able to put the building together and once they got the hang of it, the assembly process went pretty smoothly.

Shaen’s employees were able to put the building together and once they got the hang of it, the assembly process went pretty smoothly.

“One of my building maintenance people is a former engineer, so he did a great job of making sure that all of the foundation and anchor systems went in perfectly,” he said. “When the containers were positioned, everything was absolutely perfect and your roof went on exactly as it was supposed to. When you look at it, the lines are perfectly straight.”

Not only is the space beneath the roof usable, but the actual shipping containers are also used for shop space and storage space.

“We store tires and fuel, filter vessel cartridges, spare parts–everything. We’ve got a lot of square footage and absolute weather protection,” Shaen said. “The containers have lights, power outlets, and we have roll-up doors or man doors in them.“

Shaen says he’s received several comments on how much nicer the brand new maintenance shelter looks.

“Most people that looked at it saw what it replaced, so they have that contrast in your favor. I don’t know how what we had lasted as long as it did. It wouldn’t take one more minor storm let alone 130 mile winds. If we have a problem here, we’re all going under your roof.”

Shaen’s so pleased with the new maintenance shelter that the company plans on purchasing another container cover roof system for Air Service Hawaii’s newest terminal on the island of Kauai.

“We did not include a plan for a maintenance facility in the original construction, but we’re so happy with this that at some point we plan on building a similar structure with two 40 foot containers,” he said.

“I would recommend SteelMaster’s solution to anyone who’s looking for something like this. The people I’ve communicated with have been friendly, knowledgeable, professional and responsive. Don’t really need more than that!”

Categories