Our bulk storage domes keep our customers better equipped to handle dangerous roads during severe weather.

Plus, bulk materials are protected from rain and snow, eliminating the possibility of salt leaching into streams and groundwater.

Phone Exclusive: FREE SHIPPING to select locations!

Call now!

Cost effective solutions for salt buildings, sheds & barns.

We provide high-quality, custom storage that allows companies, Departments of Transportation and municipalities to protect sand and salt piles year-round.

Our bulk storage domes keep our customers better equipped to handle dangerous roads during severe weather.

Plus, bulk materials are protected from rain and snow, eliminating the possibility of salt leaching into streams and groundwater.

SteelMaster has worked with several state transportation departments across the United States. Local municipalities use SteelMaster Buildings as their supplier of choice to store and protect salt, sand, and other bulk materials from the elements.

Are you a procurement manager? Schedule a call today!

Check out real-life SteelMaster projects & learn more about:

Maximize the life of your salt stockpiles with a durable, environmentally conscious, cost effective solution.

Our salt buildings can be deployed in a fraction of the time compared to a traditional salt storage dome.

Our team of knowledgeable engineers is able to customize our steel structures to fit any budget or timeline.

Our salt and sand storage buildings are wide enough to accommodate transloading with trucks and bulldozers.

Our steel arches offer superior corrosion resistance to the elements and are engineered to meet your area’s snow and wind loads.

Most of the salt buildings we sell are custom-designed to meet unique usage, environmental regulations, and code requirements. Depending on the building’s site, various configurations may be appropriate for your building. These include:

Form Capture Name in CRM: English - Commercial Product Page Form

"*" indicates required fields

By adding my phone number, I agree to receive recurring text messages at the phone number provided from SteelMaster Consent is not a condition to purchase. Carrier & data rates may apply. Message frequency may vary. Reply STOP to cancel. Reply Help for more information. View our Terms of Service for details.

Quonset hut buildings have clear advantages over fabric salt storage or traditional salt domes.

| Structure Type | Portable | Durable | Expandable |

|---|---|---|---|

| Steel Storage |

|

|

|

| Fabric Storage |

|

|

|

| Wood Storage Dome |

|

|

|

View our catalog to see how companies are using SteelMaster buildings to create standout spaces for work, storage, and more.

What’s inside:

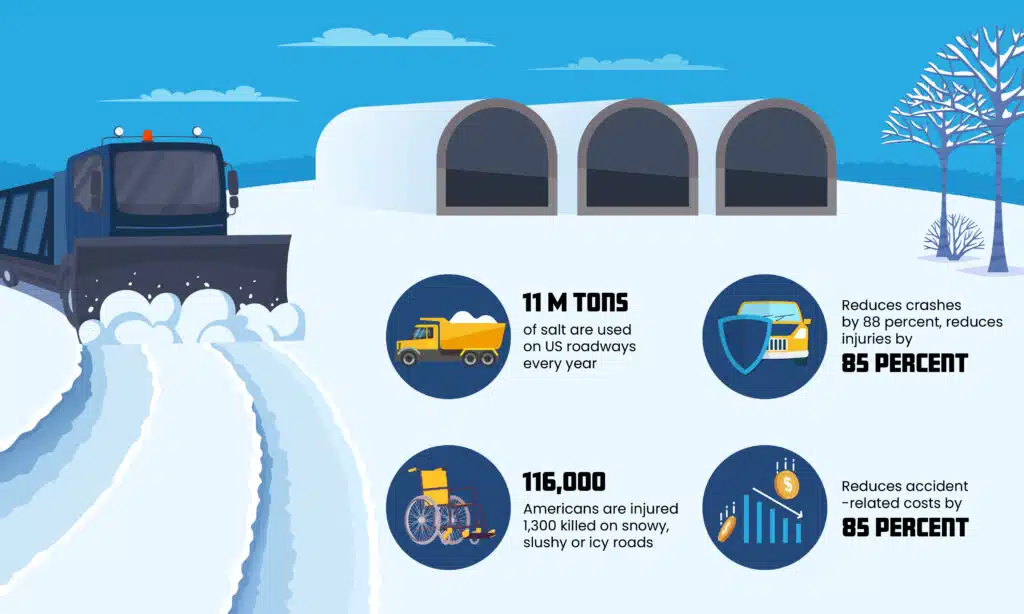

Road salt, also known as rock salt, lowers the freezing point of water, which makes it difficult for water to freeze and create hazardous road conditions. Using salt to de-ice roads has reduced crashes by 88 percent and injuries by 85 percent so spending the time and money storing it for when it’s needed is well worth it for municipalities and DOTs across the country.

Like salt, sand piles need to be covered in a way that eliminates runoff and prevents clumping. SteelMaster salt buildings can provide the same bulk material protection to sand piles and are the building of choice for many public works departments and departments of transportation.

Frac sand storage is another common use for salt buildings, used to keep the more expensive frac sand pure and ready to use for mining. This can eliminate the need for frac storage tanks or frac bins for sand storage and provide an ideal solution for frac sand transloading facility operations with plenty of room.