Whether you are a construction novice or an expert, Quonset huts are easy and quick to assemble. Every steel panel of your Quonset barn kit is pre-drilled and pre-punched right at our factory. The entire building only requires one size nut and one size bolt to put together. All you need are a few tools, a few friends, and a few days to put together a SteelMaster Quonset Hut.

New England Steel Buildings

Steel building kits designed just for New England.

Prefab Buildings, Sheds, Garages, and Barns Spanning New England

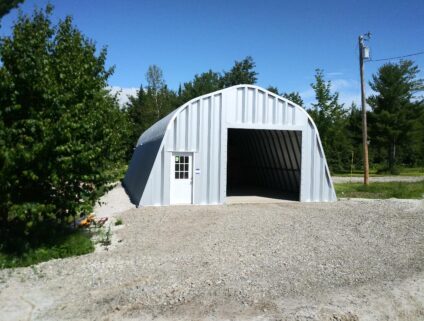

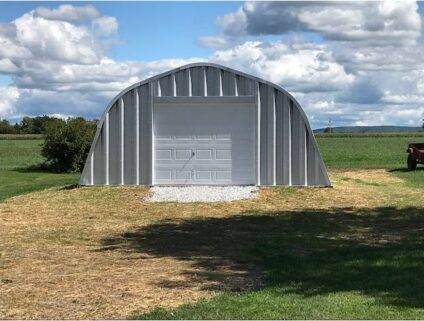

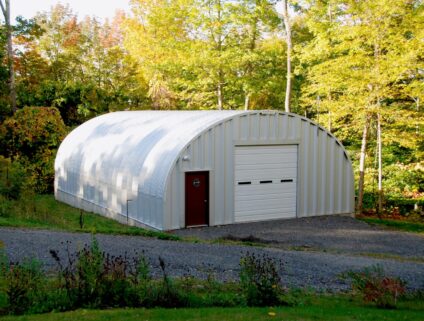

From garages to barns, SteelMaster will deliver our durable and versatile Quonset Huts to any location in the 500 mile span of New England. Not only will our plans meet or beat building engineering requirements, they will also save you time and money by making it easy to create the building of your dreams in just a few simple steps.

New Hampshire & Rhode Island Metal Buildings: FAQs

Can Quonsets protect the agricultural commodities of New Hampshire and Rhode Island?

Like most states in the New England region, some of New Hampshire and Rhode Island’s commodities include hay and corn. The three states have approximately $16.2 million in value of production for hay and haylage. Haylage is forage that is baled at a higher moisture content than dry hay. It is then stored in sealed plastic wrap.

Choosing the proper storage method can maximize nutritional value and savings. SteelMaster metal Quonset Huts can help to preserve the quality of hay and haylage by keeping bales protected from the elements of weather. Our steel prefabricated barn kits are the perfect choice for storage for agricultural equipment and products. With widths of up to 150 feet and unlimited lengths, a steel building can be used for all of your storage needs, from hay and haylage to tractors

Are Quonset hut barn kits easy to assemble?

Yes! SteelMaster’s Quonset Hut barn kits are specially designed for easy construction and hassle-free maintenance for the life of the building. Every building is prefabricated and pre-punched at our factory. Each building only requires the use of one size nut and one size bolt to construct. You don’t need an expensive contractor or construction crew; over eighty percent of customers assemble their own building, resulting in huge labor cost savings.

Where was the first Quonset hut created?

The first Quonset Hut was built at the Davisville Naval Construction Battalion Center at Quonset Point, Rhode Island. These pure steel, semi-circular Quonset Huts were originally used as barracks, latrines, offices, medical facilities and isolation wards during WWII.

Vermont Metal Buildings: FAQs

What agricultural commodities is Vermont known for?

The production of maple syrup is very popular in New England, but Vermont produces the most maple syrup in the United States, with more than half a million gallons each year. The total value of U.S. maple syrup production was $147 million in 2016. Turning maple sap into syrup requires a long process of boiling down the sap. This process is often done in what is known as a “sugar shack” or “sugar house.”

Are Quonset huts good for agricultural storage?

Yes, for several reasons. Because the Quonset hut’s arches are self-supporting, building owners can use 100 percent of the space on the inside for any machinery, products, and tools needed.

Additionally, each building is specifically engineered to endure the harshest weather conditions. The corrugated, commercial-grade steel combined with the amazing strength of the arch design help to make SteelMaster’s barns some of the strongest on earth. Our buildings have survived dangerous hurricanes, destructive tornadoes, hail storms, and even heavy snow loads after a brutal winter storm.

Are Quonset barns easy and cheap to assemble?

Maine Metal Buildings: FAQs

Can I use a Quonset hut for aquaculture?

Aquaculture, the farming of aquatic organisms like fish and shellfish, has been present in Maine since the 1800s. Today, Maine’s fishing industry is mainly focused on salmon farming. Maine accounts for 18 percent of the U.S. domestic salmon market. Many SteelMaster customers in the aquaculture industry use their buildings as fish and shellfish hatcheries by the water. Additionally, the organic Galvalume Plus coating on our panels protects buildings assembled in harsh coastal environments.

How do I assemble a Quonset hut?

You can assemble a Quonset hut in a few steps:

Step 1: Pre-construct your arches on the ground

Step 2: Raise and connect arches one at a time

Step 3: For every 4th arch raised, tighten bolts completely

Step 4: Install endwalls (optional)

Connecticut Metal Buildings: FAQs

What are the benefits of Quonset sheds?

SteelMaster’s durable, affordable prefabricated storage sheds are a perfect way for nurseries to store wheelbarrows, shovels and other gardening tools. We offer a variety of easy-to-build prefabricated shed kits to help you find a safe, durable storage space for all of your valuable items. We offer a variety of sizes from a small 10’ x 10’ to a 30’ x 30’ for larger items. No matter the size, we can design a metal shed for any purpose.

Can Quonsets be used for animal run-ins?

Our buildings can also be used as a place for animals to seek shelter, rest, and feed. The buildings are able to be open on both ends, one end or closed. The steel walls will also resist breakage when kicked by animals. To clean the building, simply dampen a cloth and use a bit of soap to wipe down the steel arches.

Disaster Resistant Buildings

While the climate in New England varies across the region, our metal Quonset Huts can handle nearly any disaster. From heavy snowstorms to ice storms, SteelMaster’s durable structures are designed with your safety in mind.

Snow Resistant

SteelMaster’s durable, metal Quonset Huts are engineered to handle the heaviest snow loads. If your home isn’t prepared or designed sufficiently, the weight of heavy ice and snow can cause the roof to collapse. SteelMaster’s metal buildings are able to handle the snow load of virtually any region. Our steel buildings follow the snow load provisions required by the ASCE 7-95 and the IBC. Many localities and zip codes also add their own specific codes for their areas.

Our arches are created with commercial-grade, high-quality steel that can be customized to accommodate extremely heavy snow loads in areas that experience frequent snow storms. Any of our models can accommodate these loads, but the X-Model has a 4:12 pitched roof, which makes it easier for heavy snow to slide right off.

Hurricane Resistant

Coastal states from Texas to Maine are at risk of hurricanes, with the main risks being flooding due to coastal storm surges and inland flooding due to rain and severe winds. It’s rare for hurricanes category three or greater on the Saffir Simpson scale to hit the region, but it’s always a good idea to be prepared. Due to the increase in New England’s population and resources in the region, an intense storm would likely result in approximately $17 billion of property damage, according to research from Brown University.

We design our structures to meet the building codes for hurricane-prone areas which change frequently with the increase of tropical depressions. Our high-grade commercial steel has the best high-speed resistance of any other kind of building.

Wind Resistant

SteelMaster’s High Velocity Hurricane Zone-certified metal buildings are some of the strongest structures on Earth. Instead of having to build an internal structure, we’ve designed each panel with deep corrugation, which gives it super strength. Each panel is overlapped and bolted to the next. This creates one continuous structure able to resist the force of strong winds by distributing the force to the ground instead of causing the building to collapse.

Hurricanes can pack winds from 74 mph as a category 1 to over 157 mph or more as a category 5 according to the Saffir-Simpson Hurricane Wind Scale. Poorly constructed, rigid frame structures are left defenseless against the power of the hurricane’s howling winds, but SteelMaster’s cyclone-proof house materials have endured when tested in the most powerful storms.

Massachusetts Metal Buildings: FAQs

What's the most common Quonset application in Massachusetts?

Today, metal Quonset Hut garages are the most popular application for SteelMaster’s residential customers. SteelMaster’s prefabricated metal garage kits are designed with the average homeowner in mind. Most buildings don’t require an expensive construction crew or experience to assemble. We make the process super simple.

Our garage packages come with all of the pre-engineered materials you need to easily put together your own DIY garage. The kits are also engineered for your specific location. If you live in an area that has heavy snow, extreme winds, or dangerous ice storms, each SteelMaster garage kit is specially made to survive the climate conditions of any location.

New England certified buildings

Talk to a building specialist

Form Capture Name in CRM: English - Contact Form

"*" indicates required fields

By adding my phone number, I agree to receive recurring automated text messages at the phone number provided. Consent is not a condition to purchase. Messaging & data rates may apply. Reply STOP to cancel. View our Terms of Service for details.