When (and When Not) to Use a Container Cover Workshop for Your Business

Container cover workshops are a popular choice for businesses looking for flexible, cost-effective workspace, but they aren’t always the right solution for every situation.

Here’s a quick guide to help you decide when a container cover workshop makes sense and when a steel building might be the better choice.

Use it: You Need Covered Space Fast

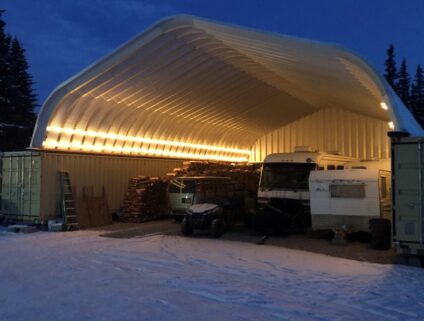

A container cover is the smarter choice for time-sensitive workshop projects. When speed is the priority, container cover roof kits help businesses stay operational and protect assets almost immediately.

In addition to typically fast shipping and delivery turnaround, construction itself is quick and straightforward. The arch panels use a single nut and bolt size to put together, which simplifies assembly and reduces downtime on site.

With a small crew, many container cover workshops can be assembled in a matter of days, providing covered space for equipment and vehicles without a lengthy timeline.

Lose it: Your Area Has Highly Restrictive Zoning or Permitting

Local regulations can make or break a project. In some areas, zoning codes or permitting requirements mandate traditional steel buildings or restrict the use of container-based systems altogether.

If navigating these restrictions would delay your project or require extensive modifications, a building may be the safer option.

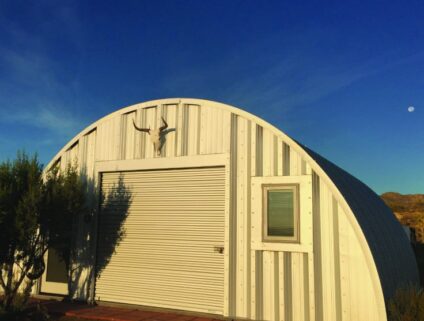

Use it: You Already Have Shipping Containers

Container cover workshops use shipping containers as the base of the structure, so if you already own them, much of the groundwork is already in place.

For businesses that already own containers, this can significantly reduce overall project costs since the foundation and primary support is essentially built in. Containers do not necessarily need to be brand new, but they should be structurally sound and free of excessive rust, major dents, or damage that could weaken the structure.

Lose it: Containers Are Scarce or Difficult to Obtain in Your Area

In regions where shipping containers are expensive, hard to source, or difficult to deliver, container cover workshops may lose their cost advantage.

If securing containers introduces delays, added costs, or logistical headaches, a steel building might be a more predictable choice.

Use it: You Want a Lower Upfront Investment

Container cover workshops are often more affordable upfront because they eliminate many of the cost drivers associated with traditional construction.

The shipping containers serve as the primary structural base, which reduces the need for extensive foundation work. Rather than building entirely from the ground up, businesses can use existing structural elements.

The simplified construction process also helps keep costs down. Prefabricated roof components are designed for efficient assembly, which can reduce labor requirements and costs, plus shorten time on site. When compared to a conventional building that requires more materials, specialized trades, and longer timelines, container cover workshops offer a way to create usable covered space while preserving your budget for other business needs.

Categories

Tags