Air Service Hawaii Upgrades FBO Maintenance Shelter with Container Cover

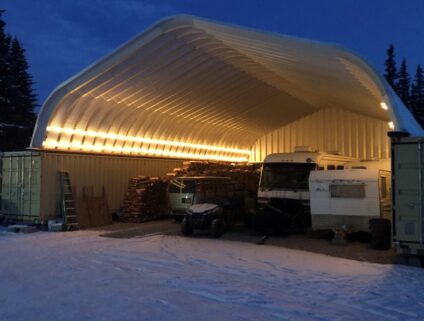

Air Service Hawaii, a long-standing Fixed-base Operator (FBO), recently upgraded their facilities. They replaced an aging maintenance shelter with a durable solution. The new structure utilizes two shipping containers and a container cover roof kit.

This upgrade replaces a structure made of weak materials. Shaen Tarter, President of Air Service Hawaii, described the previous building.

“The previous structure that was here was sort of an ad hoc, hodgepodge of the roof and flimsy supports and an old container van,” Tarter said.

About Air Service Hawaii & Storage Needs

Air Service Hawaii has operated since 1948. They currently have locations at six airports. Their primary services include:

- Ground handling and fuel for business jets.

- Refueling for commercial airlines.

- Support for touring helicopters and flight schools.

As an established business, they came to SteelMaster with a specific set of requirements for upgrading their facility. This included:

- A long-term storage solution.

- Little to no maintenance.

- No welding (an expensive service in HI).

- Compliance with FAA and HI building code standards

The Unique Challenges of Building in Hawaii

Construction in Hawaii presents distinct logistical and environmental hurdles. Buildings must survive severe weather events and meet strict local codes.

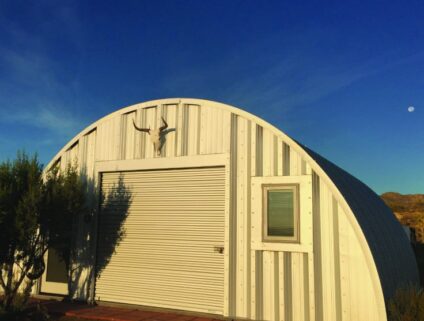

1. Hurricane Compliant Structures: in Hawaii must withstand high wind loads. Tarter noted that the previous structure would not survive another minor storm. The new structure needed to meet hurricane standards and withstand 130 mph winds.

2. Ventilation Requirements: The tropical climate requires structures to allow for airflow. Tarter selected the SteelMaster kit because the arch design offers significant headroom. This height allows breeze to flow through the workspace.

3. Space Limitations: The FBO needed a solution that fit their existing footprint. They could not relocate to a new area. The container cover allowed them to build a compliant, secure space on the ground they already owned.

Selecting the SteelMaster Solution

Tarter discovered SteelMaster through an online search. The clear span design was the deciding factor.

“The arch is necessary to create the strength, but also gives you the benefit of having a lot of headroom,” Shaen said. “In our case, the more headroom the better.”

Jon Hunter, B2B Operations Manager at SteelMaster, collaborated with Shaen’s engineer in Hawaii. Together, they designed a shelter that satisfied airport regulations and local engineering requirements.

Installation and Assembly

Air Service Hawaii employees handled the assembly process. Tarter noted that the process went smoothly.

“One of my building maintenance people is a former engineer, so he did a great job of making sure that all of the foundation and anchor systems went in perfectly,” he said.

Once the containers were positioned, the roof installation was precise. Tarter observed that the lines of the structure were perfectly straight.

Maximizing Utility and Storage

The design offers dual utility. The area beneath the roof provides workspace, while the containers offer secure storage.

The containers feature lights, power outlets, and roll-up doors. The company uses this space to store:

- Tires and fuel.

- Filter vessel cartridges

- Spare parts and other inventory

Results and Future Plans

The new structure provides absolute weather protection. Tarter mentioned that the visual contrast between the old and new structures is significant. He also noted the safety of the new building.

“If we have a problem here, we’re all going under your roof,” Tarter joked regarding the durability of the steel arches.

Due to the success of this project, Air Service Hawaii plans to purchase a second unit. They intend to install a similar structure with two 40-foot containers at their newest terminal on the island of Kauai.

“I would recommend SteelMaster’s solution to anyone who is looking for something like this,” Tarter said. “The people I’ve communicated with have been friendly, knowledgeable, professional and responsive.”

Categories