*Keyway foundation is standard on all buildings. Industrial Base Foundation option shown is for illustration purposes only

Why Us

Why Choose SteelMaster for your building project

SteelMaster has been a leader when it comes to producing some of the best quality steel products on the market.

We work extremely hard to provide excellent customer service and we always have amazing deals, but those are not the main reasons why customers keep coming back–it’s the SteelMaster difference that sets us apart from other steel building companies.

| Building Features | SteelMaster | Competitors |

|---|---|---|

| Steel Grade | Premium 80 grade (80,000ksi yield) steel | 50 grade steel, has at least 60% lower yield strength than grade 80 |

| Steel Gauge | 22-13 gauge | Typically 29 or 26 gauge that is flimsy |

| Blueprints | State Stamped Engineered Blueprints | Factory plans, not state stamped and certified |

| Nuts | Hex, serrated, self-locking nuts in varying lengths | Self tapping screws or flat nuts, that can come loose over time causing leaks |

| Bolts | NZF3000S Spray Test Hardware | Grade 2 bolts are standard, wtih grade 8 available |

| Washers | LDPE washers that are industrial grade platic, tolerant of extreme hot and cold temps | Neoprene washers that are vulnerable to cracking and melting, causing leaks |

| Protective Coating | Energy Star Rated AZ180 Galvalume Plus (dry clear organic coating) | Oil coated Galvalume that rapidly fades, discolors, smudges and smears |

| Standard Coating Thickness | Metric: AZ180; Imperial AZ60 - 20% thicker than industry standard | Metric: AZM150; imperial: AZ50 |

| Warranty | 50 year warranty backed by steel mill | 10-30 year warranty, not certified by the steel mill |

Why It Matters

These differences aren’t just technical — they impact the strength, longevity, and overall value of your building. Here’s why each feature matters when it comes to real-world performance.

| Feature | Why It Matters |

|---|---|

| Steel Grade | Durability and building strength |

| Steel Gauge | Durability, snow and wind ratings |

| Blueprints | State-Stamped blueprints can help streamline permit process |

| Nuts | Avoid leaks from non-locking nuts |

| Bolts | Protects against rust |

| Washers | Avoid leaks and damage to bolts |

| Protective Coating | Protects from stains and rust |

| Protective Coating Thickness | Enhanced lifespan against rust/wear and tear |

| Warranty | Peace of mind, confidence in SteelMaster |

All Steel is NOT the Same – Better Steel, Better Buildings

When you invest in a SteelMaster building, you’ll get the most from your investment in a top-of-the-line, quality steel structure. Our steel, parts and accessories offer superior engineering on several levels.

Material Specifications

| Steel Gauge | 22-13 | Bolt | Zinc Aluminum Hex Flange |

| Steel Grade | 80 & 50 | Nut | Serrated Hex Head Locking Nut |

| Manufacturer Warranty | 50 Years | Corrugation Depth | 7.5″ & 9.75″ |

Hardware Features & Benefits

All hardware, parts and accessories are produced in our state-of-the-art factory

Commercial-grade bolts

Along with the high-quality steel arch panels, our bolts are commercial-grade

Self-locking bolts

SteelMaster bolts provide greater reliability and holding power

Salt spray tested hex nuts

Most steel building companies don’t do corrosion resistance testing with the salt spray test

Pre-recessed polyethylene washers

Added benefits of electrical insulation, shock absorption, and improved durability

Protective Coating

Best Anti-Corrosive Agent On the Market – Longevity And Durability

| Brand | Galvalume Plus (AZ60/AZM180) | |

| Composition | 55% Aluminum-43.4% Zinc and 1.6% silicon | |

| Corrosion Protection | 50 years | |

| Organic | Yes | |

| Smudge, Stain & Fade Protection | Yes |

Ready to Start Your Project?

Fill out the form below to talk to a building specialist

Form Capture Name in CRM: English - Contact Form

"*" indicates required fields

By adding my phone number, I agree to receive recurring text messages at the phone number provided from SteelMaster Consent is not a condition to purchase. Carrier & data rates may apply. Message frequency may vary. Reply STOP to cancel. Reply Help for more information. View our Terms of Service for details.

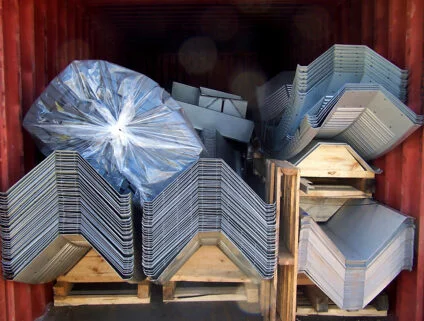

Prefabrication Saves You Money AND Delivers Quality

Prefabricated means we’ve done all the engineering of the building materials for you before your building is delivered. The buildings are cut to specifications in the factory, then shipped as a kit to the building site to be constructed.

You’ll get the precision and quality of using multi-million dollar fabrication equipment at a factory without having to pay for a custom engineered structure.

When choosing to construct a prefabricated steel building, there are big advantages:

Less expensive:

A prefab building is generally less expensive to build than a custom engineered structure. Our standard building kits are designed for do-it-yourselfers to save on high construction costs.

Easier to construct:

The components included with your SteelMaster building are made to exacting standards of accuracy for easy assembly with predrilled holes and bolts as the only required fasteners for construction. In other words, a lot of work of measuring and drilling is already done for you!

High quality:

Our state-of-the-art factory is fully equipped with the latest technology and highly-skilled production technicians who go the extra mile to manufacture superior quality products to our customers.

Our Construction Manual Takes You Step-By-Step

The SteelMaster construction manual provides you with general step-by-step information on the assembly of your metal Quonset hut kit with illustrations.

Some of the information includes:

- Storage guidelines

- Construction and building insurance

- Installation of parts and accessories (ex. Endwalls, Windows, Skylights, Vents)

- Grouting, caulking and completing the building

- Building maintenance and preventing damage

- Warranty certificate

Expert Building Specialists and Engineers – Experience To Meet Any Engineering Challenge

Established in 1982 in Virginia Beach, Virginia, SteelMaster Buildings has served over 50,000 customers from across all 50 states and over 40 countries.

SteelMaster’s team of building experts and engineers has the experience to manage a variety of engineering requirements. We will work with you every step of the way to figure out the design and specifications you need to create the steel Quonset hut you envision.

Included with SteelMaster Building Cost

✓ State-stamped factory blueprints

✓ 50-year warranty

✓ In-house engineering staff

✓ Snow, wind & seismic load analysis

Steel Barns vs. Pole Barns

When choosing a building, it’s important to look at all of your options. Here are some differences between pole barns and SteelMaster metal barns.

Steel Buildings vs. Fabric Buildings

From the clear span design to overall shape, steel buildings and fabric buildings seem to have a lot in common. However, there are significant differences that set SteelMaster metal buildings apart from fabric-covered structures.

Engineer For The Worst and Hope For the Best – Disaster Resistant Engineering

Technically speaking, no building company can claim that their building is 100 percent disaster proof, but our buildings are built to withstand a wide variety of environmental factors.

Why Us: Our Logistic Experts Plan A Cost-Effective & Timely Delivery For You

We make getting your new building from the factory to you an easy process with complete transparency.

Speed, Efficiency, and Logistics Expertise

Whether your building is delivered by a tractor-trailer or bundled on ballets in containers to be shipped overseas, our knowledge of logistics will ensure your building arrives with everything you need.

We Detail and Finalize the Shipping Process With You

We’re only happy when you’re happy and a big part of that is the peace of mind of knowing you have a professional team of shipping and logistics experts at your disposal.

We can work directly with you to help set up and manage the shipping and delivery process. Our team of professionals has extensive knowledge of transportation document requirements including:

- Bill of ladings

- Certificate of conformity

- Export and import licensing requirements

LEED Certified Buildings – Eco-Friendly While Still Being Budget Friendly

Due to steel’s recycled content and functional properties, building products made from our steel can be credited with the maximum number of points for the Materials & Resources Credit aspect of the LEED rating system.

Our steel building products contribute positively toward points under credits 4.1 and 4.2 of the LEED rating system:

- Credit 4.1 (1 point) “Use materials with recycled content such that the sum of postconsumer recycled content plus one-half of the pre-consumer content constitutes at least10% (based on cost) of the total value of the materials in the project.”

- Credit 4.2 (1 point) “Use materials with recycled content such that the sum of post-consumer recycled content plus one-half of the pre-consumer content constitutes at least 20% of the total value of the materials in the project.”

In addition to recycled content, steel can contribute toward several other LEED credits, either directly or indirectly.

Our in-house LEED Engineer William Swafford, has received the U.S. Green Building Council’s (USCGB) Leadership in Energy and Environmental Design (LEED) Green Associate certification.

CALIMA Paca & Piggie Sanctuary

Noah was able to come up with a design and a fair price in just a short time.

Waiting for enclosure to show in the Spring when winter breaks here.

Not everyone wants a sales person calling them.

We ended up with building then I might have gotten else where. No pressure. That’s the way to go.

All in all Steel Master folks were very responsive and I would definitely recommend them and their buildings!

I’m very pleased with the whole project. I just wish I could have afforded longer building.

I use it as winter storage and shop.

There are a great company to do business with.

Very professional, and courteous.

Gave me a great deal on a storage building.

Thanks Steelmaster David

The base was a life saver for me. I recommend it for anyone who wants to install the building themselves.

I am almost 70 years old and if I can install two buildings anyone can.

Very good customer service.

Received my order quickly and with excellent communication.

service,great communication and valuable

follow.

I highly recommend them and couldn’t be more please!!

I bought my first Quonset hut from steel Masters and it went up easy and it was affordable I would recommend this place to anybody that wants a steel building.

Once we had a good idea what we wanted, we had a call with Tyler who layed out the options and process. It was easy to follow and we chose to include front and back end walls as well. Very excited to get our building and get started!

At my Insurance Agency. When I shopped

with my wife if someone got my attention because of there help I would put their name

in my phone. This list is how I kept a good staff.

So for SteelMaster the help was very, very

Good! JAMIE IS A Selling machine. I would put her on one of my horses anytime!

ASHLEY is what they call, “Quality Consumer

Focused Service”. I could tell she was smiling the whole time she was talking.

And, just like clockwork I get an email from Elizabeth.

Giv ‘em all a little raise! Tom Hanson

THUNDERHEAD

RANCH

My sales rep Gordon did a great job finding me a great deal on a building even larger than I was hoping for. I was able to get the base plates for half of the original quote so I have to say thanks to Travis for working g with the owner to get a price we could both agree to.

Tha m you steelMaster

I was able to take advantage of several discounts, one being a veterans discount.

The customer service was phenomenal.

Definitely do your research before making your purchase to ensure that you are getting the best fit.

Look online at their website to see some of the options you have available.

I would absolutely purchase another if I ever need one.

Julius

Bill Reed

Lutz florida

Whenever I needed additional support the SteelMaster USA team was just a phone call away and went the extra mile to meet all of my needs. The investment I made in the steel building has proved to be a wise choice and one that my family will enjoy for generations.

If you're contemplating a steel building for whatever use case you may have, make sure you contact SteelMaster USA.

Very knowledgeable personnel, easy communication”s. Quick & Easy Thanks SteelMaster!

When my city held up my building permit for nitpicky reasons, Noah and SteelMaster Buildings went to bat for me and had their engineers contact my city and get the problems ironed out.

I had done my reading, and I knew the delivery date and time of the truck that was delivering my parts and I knew I had to unload the truck myself. That went smoothly and was unloaded in about 15 minutes.

I checked over the parts, and I was missing 3 washers. I informed Noah the same day as delivery and he made sure to get them for me before I began construction.

After reading the construction manual several times, watching some videos and reading other's building tips, I began construction. I rented a scissors lift to make erection easier and I never had more than 3 people helping, most times it was 2 people.

I made sure to check the height after each arch, and jacked up each arch with a small bottle jack. Construction went smooth, and everything went up easily and aligning all the bolt holes was not bad.

When we had the arches constructed and went to insert the remaining bolts, 95% of the holes lined up so well that all we had to do was to drop the bolts in the holes.

We have had some really hard thunderstorms this summer, and after the first storm I noticed a leak, more of a drip really. I tracked it down to one single bolt that we had failed to tighten. I tightened up that bolt and since have had absolutely no drips or leaks.

Overall, I couldn't be more pleased with my SteelMaster Buildings experience!

Dan

July 2023

About the things I was concerned about, which made it easy to Decide.

Now We will see if the installation goes as smooth as the sale . .

Michael

Will work with you on pricing. Product specifications seem of high quality.

Waiting on delivery and excited to erect the building.