After your building is designed, it is usually packed onto the bed of a flat bed truck.

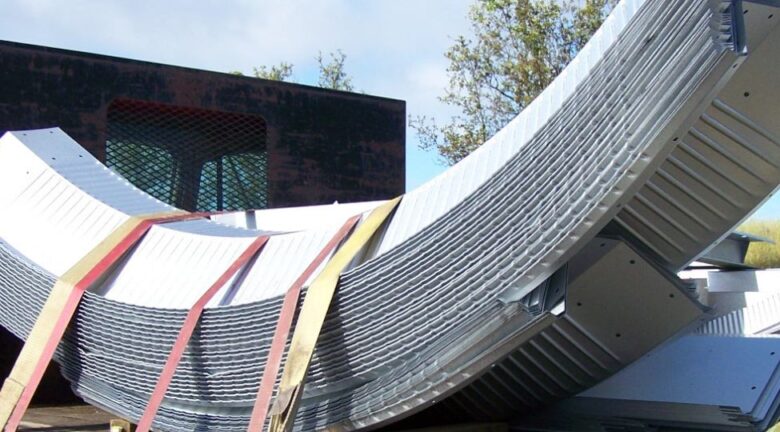

The panel design of metal Quonset huts makes shipping easy. The panels are stacked on top of each other and often covered with a tarp for additional protection. The heaviest arch panel in 22 gauge is about 40 pounds.

The panels and a bucket of bolts for your building are loaded and secured on a truck to ship to your destination. Several buildings can fit onto the truck depending on the size of the buildings. If you have additional parts and accessories, they will be shipped and delivered with your building.

For overseas shipping, the panels are stacked on top of each other and if required can be crated framed with wood, then covered with a metal case for additional protection. The panels are placed in a shipping container for shipment to your destination.

Several buildings can fit into a 20′ or 40′ container depending on their size. If you purchase a container cover, the shipping container can be used as one of the walls of your building so you get the most value out of your purchase.