“This is probably the best relationship I’ve had with any customer,” Scott said. “They did a lot of the work themselves and hired Amish contractors to put their buildings up.”

Meet the Team

Scott Matthews

National Sales Manager

Years at SteelMaster: 12+ years

Specialty: Homes, cabins, observatory buildings in the lower 48 states

Scott Matthews has worked at SteelMaster for nearly a decade and is currently a National Sales Manager.

He has sold many different types of buildings to customers and is one of the “go-to” representatives for Quonset hut home projects. In addition to connecting with customers across the United States, Scott loves the education aspect of his job and the company’s “family atmosphere.”

“At SteelMaster, you get support from every direction. It’s a family. I can’t remember going to anybody in the office and asking a question and not getting help.”

Notable Projects

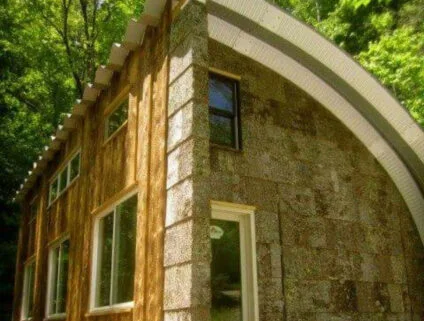

House in Missouri

Among all of the unique houses and architecture on a large recreational lake in the Midwest, you’ll find Tom and Kim’s SteelMaster Quonset hut lake home. After enlisting the help of an architect to design their home, Tom and Kim began construction of their home in the fall of 2017. Scott has helped many customers with their Quonset hut home projects during his time at SteelMaster.

Workshop in Smiths Grove, Kentucky

Mark Whitley is an award-winning artist and musician. When he’s not spending time with family or working on music, Mark spends hours in his shop creating some of the most spectacular wooden masterpieces.

In addition to building his own special wooden endwalls, Mark also installed wooden floors to allow adequate airflow in the building to dry the wood properly. Scott says he’s honored that Mark trusts him and SteelMaster enough to be a repeat customer. He owns two other SteelMaster structures: a carport for his ‘76 Volkswagen van and a steel awning for his home.

Ready to start your project?

Contact Scott today!

Form Capture Name in CRM: English - Contact Form

"*" indicates required fields

By adding my phone number, I agree to receive recurring automated text messages at the phone number provided. Consent is not a condition to purchase. Messaging & data rates may apply. Reply STOP to cancel. View our Terms of Service for details.