Andy had an existing concrete slab, so being able to meet his foundation requirements was a little challenging. However, Noah was able to design a building engineered to meet the requirements of his situation. “He just loved the building because of the clear span and because of the hurricane wind ratings since they get super high winds down there.”

Meet the Team

Noah Taylor

National Sales Representative

Years at SteelMaster: 20+ years

Specialty: Snow and hurricane prone regions, backyard shops, garages, fully custom design build applications and state of Alaska

Noah has sold to customers in all 50 states and over 20 countries including homeowners, small businesses, farmers, Fortune 500 companies, and the US Military.

He has a vast knowledge base including project design, engineering, AutoCAD, foundations, logistics, and construction. He has a very hands-on approach to sales where he follows the project through to construction completion which is why he has so many repeat and referral clients all over the world.

“Working at SteelMaster gives you the opportunity to create solutions for people that might not know exactly what they want. They might have an idea or a concept and you can help turn that idea or concept into a complete solution for the customer.”

Notable Projects

Hunting Cabin in Kotzebue, Alaska

When customer Rod E. came to SteelMaster in search of a hunting cabin, he had some unique requirements. “They have grizzly bears in the area all the time. We actually built and designed everything to be bear proof,” Noah said. “None of the doors swing inward and instead go outward so that the grizzly bears can’t push the doors in on the building.” Additionally, Rod’s building site is in an extremely remote location. “This was like planes, trains and automobiles to get to him,” Noah said. “If you look at this location on a map, there are no roads.”

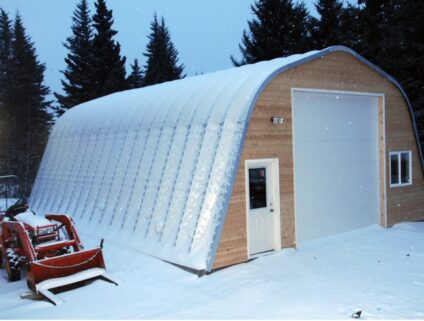

Alaska Pole Vault Club in Salcha, AK

For SteelMaster customer David B., pole vaulting is a family affair. David is a second-generation pole vaulter and started pole vaulting in 1984. It’s now a hobby he shares with his two sons and daughter. However, living in Alaska, the window of opportunity for outdoor pole vaulting is short due to the harsh winters. That’s when David came up with the idea of building an indoor facility. “This was probably one of the most challenging jobs I’ve ever done,” Noah said.

Ready to start your project?

Contact Noah today!

Form Capture Name in CRM: English - Contact Form

"*" indicates required fields

By adding my phone number, I agree to receive recurring automated text messages at the phone number provided. Consent is not a condition to purchase. Messaging & data rates may apply. Reply STOP to cancel. View our Terms of Service for details.