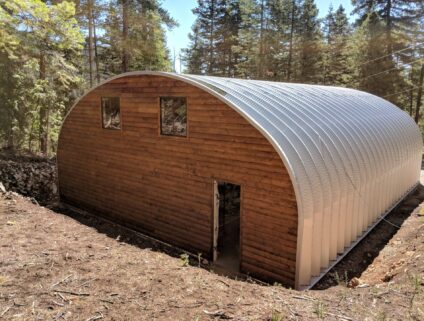

Customer Kyle D. contacted SteelMaster when he wanted a unique, custom home that would handle southern Maine’s heavy snow loads. Cameron worked with Kyle and his contractor for almost two years to bring the project to fruition. Cameron suggests that customers interested in a Quonset hut home take the time to think about all aspects of their building’s design.

Meet the Team

Cameron Cotterell

National Sales Manager

Years at SteelMaster: 7 years

Specialty: Heavy snow region, custom build homes, state of Hawaii

National Sales Manager Cameron Cotterell has worked at SteelMaster for five years and is an expert on all things Quonset.

He says his favorite part of working at SteelMaster is working on custom projects.

“I always like something that piques my interest. I like something that’s going to be a challenge, where I can also learn something. Even after being here for five years, I still feel like I learn something new every day.”

Notable Projects

Barn in Coleman, Michigan

Katherine and Jeff S. purchased a custom steel garage after their barn was destroyed in a massive fire.

“They never wanted to experience anything like that again so they went through the process with us to find one that worked for them,” Cameron said.

SteelMaster’s custom arches are built strong enough to withstand almost any disaster. Cameron says the project was very memorable for him since he was able to help the couple find a safe solution that fit their needs.

“It’s one of my favorite projects I’ve ever done,” Cameron said.

Garage in Pollock Pines, California

In March 2020, Mother Nature threw Mark a massive curveball. It snowed four feet in just two days at his property in California–something that’s not typical for that area. Although there was damage to his SteelMaster building, all of Mark’s belongings inside were completely fine, including his pickup truck.

“I think that [the SteelMaster building] probably is better than my other 40×40 building, even though it’s got a lot of heavy-duty red iron up on top. It wouldn’t have done as good as [a SteelMaster],” Mark said.

Ready to start your project?

Contact Cameron today!

Form Capture Name in CRM: English - Contact Form

"*" indicates required fields

By adding my phone number, I agree to receive recurring automated text messages at the phone number provided. Consent is not a condition to purchase. Messaging & data rates may apply. Reply STOP to cancel. View our Terms of Service for details.